Skip to Content

Currency

-

PCB Fab

-

PCB Assembly

-

Acrylic Cutting

-

3D Printing

PCB Fab

How does pcbwave PCB work?Only accept zip or rar, Max 30MB

Please contact our customer service team for any special requirements. To ensure that your order goes smoothly, we recommend double-checking your designs with CAM350 for errors before placing your order.

For PCB orders placed directly on this page, please remember that any changes or notes to your file need to be made before 6:00 p.m. of the same day (Beijing Time). If you need to make changes within the allowed time, please send an email directly to PCB@pcbwave.com .

PCB Stencil

PCB Assembly Service

How does pcbwave PCBA work?Please note: Price does not include the cost of components, exact quotation will be sent to you via email after you contact Service@pcbwave.com for help.

Need a quick and accurate quote? Please prepare the Quotation Documentation according to our document format The template for necessary files. Thank you very much!

Acrylic Laser Cutting

How does pcbwave Acrylic Laser Cutting work?Only accept zip or rar, Max 30MB

If you have any other special requirements, kindly contact our customer service: PCB@pcbwave.com.

If manual quotation is required, please send the files to: Service@pcbwave.com.

To avoid errors, the preferred design file is DXF format. please also include the exported PDF file in the design file.

Special offer of $1 for 5pcs Acrylic only works for your 1st project each day.

3D Printing

How does pcbwave 3D Printing work?Multiple 3D files can be uploaded at the same time(Max 10 files) , Single file size max 30MB

only supported STL file for Auto Quotation

Special offer of $1 for 1&2pcs 3D Printing only works for your 1st project each day.

PCB Cost

USD$4.90

-

Layer2 layers

-

Dimensions100mm * 100mm

-

PCB Qty5

-

Different PCB Design1

-

PCB Thickness1.6

-

PCB ColorGreen

-

Surface FinishHASL

-

Castellated HoleNO

-

Copper Weight1oz

PCB stencil Cost

USD$

-

Stencil type

-

Size (mm)

-

Stencil Side

-

Quantity

-

Mark point

PCB Cost

USD$30.00

-

Assembly CostUSD$

-

Project manager will give the quotation within 1 working day after you submitted enquire.

Acrylic Orders

USD$1.00

-

Dimensions100.01mm * 100.01mm

-

Acrylic Qty5

-

Acrylic Thickness2

-

EngraveNO

-

Acrylic ColorTransparent (000)

3D Printing

USD$0.00

The Regular Custom PCB (On-line Ordering) service will provide you the PCB with the parameters shown in this page. All the PCBs will be fully tested, not random test. If there is any problem for your order or any suggestion for our service, please contact us via service@pcbwave.com, order@pcbwave.com, techsupport@pcbwave.com, qc@pcbwave.com.

|

Gerber Files Required (2-layer) The following files are needed for the PCB production: |

|||||

| TOP LAYER: | pcbname.GTL | BOTTOM LAYER: | pcbname.GBL | ||

|---|---|---|---|---|---|

| SOLDER STOP MASK TOP: | pcbname.GTS | SOLDER STOP MASK BOTTOM: | pcbname.GBS | ||

| SILK TOP: | pcbname.GTO | SILK BOTTOM: | pcbname.GBO | ||

| NC DRILL: | pcbname.TXT | MECHANICAL LAYER: | pcbname.GML | ||

|

Gerber Files Required (4-layer) Including the layer shown in “Gerber Files Required (2-layer)”, and two inner layer should also be added: |

|||

| INNER1 LAYER: | pcbname.G1 | INNER2 LAYER: | pcbname.G2 |

|---|---|---|---|

|

Specifications |

|||

| MULTI LAYERS: | 1-2-4-6-8 | PCB MATERIAL: | FR-4 |

|---|---|---|---|

| AVAILABLE COLOR: | Green, Red, Yellow, Blue, White, Black, Matte Black, Purple | SILK SCREEN: | White, Black (For White and Yellow Solder Mask) |

| MAXIMUM SIZE: | 55cm X 55cm | MINIMUM QTY: | 5pcs |

| BOARD THICKNESS: | 0.6mm,0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm | THICKNESS TOLERANCE: | (t≥1.0mm) ± 10% |

| THICKNESS TOLERANCE: | (t<1.0mm) ± 0.1mm | MINIMUM PCB TRACK: | 6mil (Recommend >8mil) |

| MINIMUM TRACK SPACE: | 6mil (Recommend >8mil) | MINIMUM PADS SPACE: | 8mil |

| MINIMUM SILKSCREEN TEXT WIDTH: | 0.15mm | MINIMUM SILKSCREEN TEXT HEIGHT: | 0.8mm |

| OUT LAYER COPPER THICKNESS: | 1oz(35um)/2oz(70um) | INNER LAYER COPPER THICKNESS: | 17um/35um |

| DRILLING HOLE: | 0.3mm | DRILL DIAMETER TOLERANCE (NON-PLATED): | 0.05mm |

| DRILL DIAMETER TOLERANCE (PLATED): | 0.1mm | OUTLINE TOLERANCE (MECHANICAL): | ±0.20mm |

| SURFACE FINISH: | HASL, HASL (Lead Free), ENIG | ||

|

Lead Time Example (Please make sure that you place the order before 5:30 p.m. (Beijing Time)) |

|||||

| ORDER DAY | IN PRODUCTION | 24H RUSH SHIP | 48H RUSH SHIP | 72H RUSH SHIP | 96H RUSH SHIP |

|---|---|---|---|---|---|

| Feb. 1st. | Feb. 2nd. | Feb. 3rd. | Feb. 4th. | Feb 5th. | Feb 6th. |

|

Special Requirement |

|

| 1 | For one layer PCB, we make it as 1 layer with a mask on one side in default. Please leave a comment if it should be made as 1 layer with a mask on both sides. |

|---|---|

| 2 | The board outline must be included at least in one layer if there isn't GML/GKO layer. |

| 3 | Gerber “RS-274-X” is the sole format for fabrication, and you can output Gerber from other formats, they are “BRD”, “PCBdoc”, and “LAY6”. |

| 4 | If you need some holes not plated, please name the non-plated holes as pcb.name-NPTH.txt and leave a comment. |

| 5 | For stencils, we skip through-hole component pads and all drills (holes) by default except the fiducial, so you need to leave a message to us if you need to make the holes of the GTP and GBP. |

| 6 | If you want to make your board with golden finger and beveled edge or edge copper plating, please leave us a comment or contact us at service@pcbwave.com. And you may need to pay extra for it. |

| 7 | We could make the PCB without any surface finish and leave the copper exposed, please leave us a comment on your order. |

| 8 | For panelizing, we could make your board with v-cut or mouse bite. |

| 9 | The engineer will add the manufacture time code on the board edge. If any code is not needed, please leave a comment. |

| 10 | The USD 1 PCB prototype is to encourage innovation, please don't add the same PCB design with this USD 1 PCB prototype. |

Capabilities

PCB Types For Assembly

- FR4 Rigid Board

- Aluminum Board

- Flexible Board

- Rigid - Flex Board

Part Sourcing

- Customer offers all parts

- Turn-key: All parts sourced by PCBWAVE

- Combo: Partial parts offered by Customer and PCBWAVE sourcing the rest

Assembly Options

- SMT assembly: BGA, QFN, QFP, SOIC, PLCC, PoP, 0805, 0603, 0402, 0201

- Through hole assembly

- Single&Double sides assembly

- Sub-assembly

Solding Types

- Lead free/ROHS compliant soldering only

- Hand soldering

- Reflow soldering

- Wave soldering

Quality Control

- IPC-A-610F class 2 standards

- ISO9001:2015

- IATF16949:2016

- Free Visual inspection

- X-ray Inspection

- SPI&AOI&ICT(In-Circuit Test) Testing

- Functional test

Order Processing Ability

- Minimum Order: 1pcs

- General lead time: 3 weeks (Exact lead time will be given by the project manager)

- Within 24 hours response after receiving RFQ

- Dedicated project manager for every customer

Part sourcing of the turn-key solution

- Digikey/Mouser/TME/Element 14

- Local electronic market

Value-added services

- Designing service

- Mechanical service

- Sub assembly/kitting service

- Drop shipping service

How to charge

PCBA Quotation = PCB Cost + Stencil Cost + Components Cost + Assembly Cost + Flashing/Testing Cost.

1. PCB Cost: The price is according to the PCB layer, dimension, quantity, pad finish, and your other requirements.

2. Stencil Cost: The stencil is used for the soldering of SMD components. we will use the best stencil type for you according to the project. Please also note PCBWAVE will keep the stencil for three months and it won't be shipped with the assembled boards without extra requirements.

3. Component Cost: This cost is for the components provided by PCBWAVE. The quotation sheet given by the project manager will include an exact quote for each kind of part, and it's up to you which parts are to be provided by us and which parts are not.

4. Assembly Cost: The price is affected by many factors such as the number of SMT pads, the number of THT pads, and the quantity of the boards.

5. Flashing/Testing Cost: According to the consumption of time, testing jig, and the necessary equipment for the project. We will send you a detailed quotation sheet with the above costs after receiving your RFQ and necessary files. The final price depends on the quotation sheet sent by the project manager.

What information do you need to offer

Please upload all the following information to our website

1. PCB Gerber files.

2. BOM of your project.

3. Quantity and PCB specification.

4. Parts mapping for soldering with a parts machine, or a simple mapping for hand soldering.

5. Coordinate files for machine pick-up parts.

6. Your specific requirements, or some tips you want to share with us to avoid mistakes.

7. Testing Plan.

8. Your shipping address and the shipping method you want, DHL/FedEx/OCS/registered air mail supported.

You can download >> The template for necessary files

| ITEM | INFORMATION |

|---|---|

| Quality Control | The quality of the PCBA is our core concern, PCBWAVE has a mature system such as ISO9001-certified procedure, and various testing methods to ensure manufacturing your PCBA with high quality. |

| Lead Time |

Lead time=PCB manufacturing time + Part preparing time + Assembly time + Flashing&Testing time + Packing time Generally speaking, we will prepare the parts when manufacturing the PCB. If all parts can be sourced from our local market, the parts will be ready within 7-14 days; if some parts have to be imported from Mouser/Digikey/Element14, the preparation of parts will take 10-21 days, but the final preparing time will depend on the arriving time of the last part. We will start assembling your order within 8-48 hours if all necessary files and the parts are ready. |

| Quotation | After you send RFQ to us, we will arrange a dedicated project manager for you to follow up with your project/order until it's finished. You can contact the project manager directly if you have any question or problem. The project manager will reply to you within 24 hours with detailed quotation sheet in which it includes: PCB cost, stencil cost, assembly cost, component cost(exact cost for each component), flashing testing cost and shipping cost, all costs will be listed in the quotation sheet, no other hidden costs. |

| Parts |

Offering all the parts for the PCBA from yourself are recommended. In this case, please send us all the components with BOM file and detailed packing list indicating item number, manufacturer’s part number and quantity in kit. Please contact with your project manager before you shipping the parts to us, the project manager will send you detailed notes. For turn-key part sourcing service, We help sourcing the components from our local reliable suppliers, and guarantee 100% responsible for the quality of the components, this service can decrease your costs prominently and shorten the lead time. And as stated above, you can also choose which parts to be sourced from our local suppliers and which parts must be from Mouser/Digikey/Element14/ by making a remark in the BOM sheet with Y or N. |

| Functional testing | Functional testing can make a great help for lowering the defective rate of the PCBA. Due to the complexity of PCBA production, it's impossible for any machine to have no defectives, especially for prototyping and small batch production. As we can detect and prevent the defectives flowing out through functional testing, it is strongly recommended for your PCBA project. Furthermore, we offer free functional testing service for orders over $2000 and the testing time is no more than 1 minnute for each unit. With the testing, you can receive 100% QC passed boards, that will save you a lot of time and money. For some projects, testing plan is necessary. |

| Package & Shipping | All PCBAs will be packed with ESD bag/ESD foam to prevent possible static damage, and quality carton boxes will be used to protect your PCBAs during shipping. Also, you can inform us of your packing requirements. |

| PCB & Stencil |

PCBWAVE project manager will check the gerber files and your required specifications for the quoting. The default specification would be 1.6mm thickness/hasl/green. Please check this as you receive the quotation and notify us if you need to alter the specification. A stencil is used for the SMD components soldering, with the stencil, the SMD components would be easy to solder, and it will be kept in our company for 3 months. Please note that it won't be shipped with the assembled boards without extra requirement. |

| Coordinate file | Coordinate file is necessary for machine assembly, it describes the position and orientation of all the surface mount parts, which includes the reference designator, X and Y position, rotation and side of Board (Top or Bottom).Please click here to know how to generate a coordinate file. |

| Parts Overage |

Proper SMT machine setup and operation requires parts overages, Resistors, Capacitors, Diodes (0603, 0805, 1206, 2225, SOT, SOD, MELF - packages) require a minimum of 50 pieces and have to exceed the required quantity by 30 pieces. Resistors, Capacitors, Diodes (0201, 0402, miniMelf, miniature packages) require a minimum of 100 pieces have to exceed the required quantity by 50 pieces. A small number of excess(1-5 pieces based on the total quantity of assemblies) is requested for expensive parts A small number of excess(1-5 pieces based on the total quantity of assemblies) is requested for expensive parts such as IC, BGA, QFP, Connectors, etc., this will ensure smooth assembling and punctual shipping of your PCBA. If you have any question or doubt, please don't hesitate to contact us. |

| Panelization | PCB Panelization will make a great help for assembly and testing, so we will panelize your boards acquiescently if you don't have other requirements, the stencil will match to the panelized PCB. |

| Back Order management | PCBWAVE has a mature solution to manage your back order so as to ensure the correctness and the quality same with previous batches manufactured in PCBWAVE. |

| BOM | BOM(billing of materials) shows what parts are needed to assemble the boards, and where these parts should be placed and assembled. We accept the BOM in the format of .xls, xlsx or .csv. Please settle your BOM according to our template, which is very important. A clear BOM can avoid many possible mistakes during assembly. |

| Customer satisfaction |

We cherish every relationship with customers, and making every customer satisfy with our services is our goal. PCBWAVE is 100% responsible for the mistakes/faults in the production. If there is indeed some problems in our production resulting in your lost, you can contact your project manager or service@pcbwave.com to request re-make or even refund. We are glad to hear your suggestions/complains if not satisfied, and we appreciate your recommendations to your friends with your satisfaction. |

PCB Assembly FAQ

Q: Security |

| PCBWAVE promises not to disclose any design/manufacture files and information about your project, your related designs are safe in PCBWAVE. We can assign NDA with you to ensure the safety of your project. |

Q: For the turn-key part sourcing solution,will all components be sourced from your local market? What will you do if the parts used in the PCBA are fake? |

| We will get the parts from mouser/Digikey/element14/local electronic market, you can indicate which parts should be sourced from which market. And we take 100% responsibility for components' quality problem. |

Q: Can PCBWAVE help buy parts from specified supplier by customer? And does PCBWAVE accept the components shipped from other Chinese suppliers for production? |

| Yes, we can help you to buy parts from the specified supplier, or you can pay for the supplier and ask them to ship the components to us, but we will charge you if cause any extra cost such as the taxes, currency exchange loss or the handling fee. |

Q: Why need a testing plan for customer? |

| Normally the testing plan is recommended for the turn-key service( from PCB fabricating, part sourcing to PCB assembly). As we mentioned above it is a complex work that possibly encounters errors/faults, the functional testing as the last checkpoint for the quality control, it can detect the most of defects and ensure the quality of PCBA before shipping out the assembled boards. |

Q: Does each component have exact price in the quotation sheet? |

| Yes, The quotation sheet we send you will clearly list the exact price for each component. |

Q: Is your assembly ROHS compliant? |

| Yes, we only accept lead free PCBA order, all production materials are lead free. |

Q: what should be noted if customer offers the parts for assembly? |

| Please inform your project manager before you ship the parts to us, we will send you our address and the shipping tips which can help you avoid many possible custom problems. |

Q: Why need a coordinate file? |

| Coordinate file is necessary for the picket place machine, it describes the position and orientation of all the surface mount parts, picket place machine needs it to pick the right part and place to a right position, you can export the coordinate file from your schematic design software easily. |

Q: What can I do if find defects or problems after I receive your assembly boards? |

| Please contact your project manager directly or send the email to service@pcbwave.com, we will give you a report and solution after making an internal investigation and analysis for the defective boards. PCBWAVE attaches great importance to customer satisfaction, if the mistake/fault is caused by our side, we will be 100% responsible for it. |

Q: What is the ISO9001 certification? |

| ISO 9001:2015 sets out the criteria for a quality management system and is the only standard in the family that can be certified to. This standard is based on a number of quality management principles including customer focus, the motivation and implication of top management, the process approach and continual improvement. Using ISO 9001:2015 helps ensure that customers get consistent, good quality products and services. |

Q: Do you offer rush service for PCB assembly? |

| The main factor affecting the delivery time of PCBA orders is components. It takes 1-2 weeks for all components to return to our warehouse. If your delivery date is urgent, you can tell your project manager that we will speed up the progress of your project without charging any extra fee. |

Q: Except the PCBA service, does PCBWAVE offer other services to help me bring the idea to a real product? |

| Yes, We offer one-stop services for you to bring your design to product. |

DETAILS

Laser cutting is an additional service of PCBWAVE, which is ideal for making custom parts quickly and economically for any project. We adopt the accurate technology and try our best to ensure the quality of the products. The laser cutting service can provide you with various Acrylic colors which include transparent, black, purple, white, blue, green, red and yellow, etc.

The specific parameters of the color please reference our details. The thickness of the full transparent Acrylic can be 2-50mm and about 3.0-5.0mm with the others colorful boards. There will be 0.15mm-0.2mm tolerance for the materials of different color. In addition, you can select the unique technology to make your products look different, such as, graving some logos, bending angle of 45 and 90 degrees or Arc bending, bevel, buffing, channeling, punching, tapping, and painted, etc.

Besides, you can design your favorite Acrylic products that upload your files to our website or custom dozes of Acrylic products with this service.

Note:

1.Only laser cutting quote online is available, for engraving, etching, please contact service@pcbwave.com for inquiry.

2.For easily making, please use "mm" as the unit of your design. And the CAD, CDR, AI or PDF file format is acceptable.

3.Different software will make the dimension look different, in order to minimize the error, please mark the outline dimension in your design or use a txt file in the zip file to let us know the correct dimension.

Process Description:

No.1 Laser cutting, it can cut very complex graphics, such as polygon and so on.

No.2 Graving, which includes Yin carving and carving that adopting the new laser and light projections technology.

No.3 Bending, an angle of 45 or 90 degrees. Full angle of science bent, durable and beautiful.

No.4 Arc Bending, which is a fast and convenient technology about professional profile bending.

No.5 Chamfering of edge, it can produce the smooth edge and will not hurt your hand.

No.6 Buffing made the product like diamond and the technical definition is as high as 95% above.

No.7 Bonding and Molding that is waterproof seamless combined bending.

No.8 Punching, we can open side hole, inclined hole, countersunk head blind hole and don’t leaned accurately.

No.9 Tapping, which is a Professional and stable technology, highly accurate and has the clear thread.

No.10 Channeling made a groove milling machine clean level, beautiful appearance.

No.11 Silk-screen or Print, which is color printing and the products are carved milling material color.

No.12 Painted Using the grind arenaceous black spray paint, after four working procedures and not easy to fade durable.

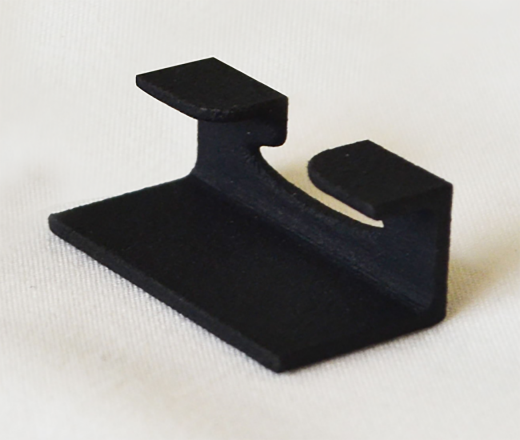

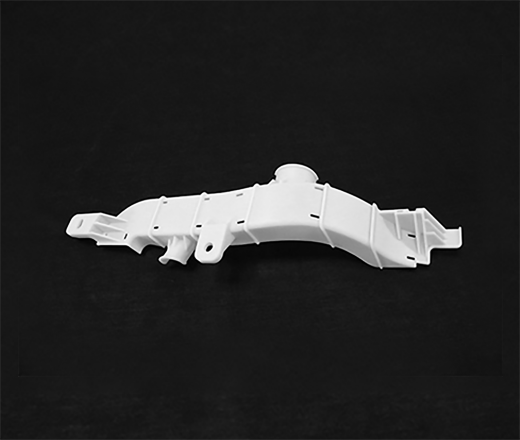

3D Printing Materials Available

Tell us which material do you need in the email, we will quote for you.

| Picture | Material Name | Characteristic | Physical Specification | Common Use | Maximum Molding Size (mm) |

|---|---|---|---|---|---|

|

Nylon | The surface is grainy and white. Toughness: good toughness and high fracture ductility. |

Density: 1g/cm^3 Working Accuracy: ±0.2/100mm Temperature resistance:145℃ Tensile Strength: 46MPa Modulus of Elasticity:1602MPa |

Auto parts, household appliances, electromechanical equipment | 350*350*420 |

|

Black Nylon | The surface is grainy and black. Good toughness and high fracture ductility. |

Density: 1.03g/cm^3 Working Accuracy: ±0.2/100mm Temperature resistance:88℃ Tensile Strength: 23MPa Modulus of Elasticity: 541MPa |

Automobile, consumer electronics, electromechanical | 330*330*400 |

|

Nylon + Glass Fiber | The surface is grainy and white gray. Toughness: the material has better strength and better mechanical properties. |

Density: 1.26g/cm^3 Working Accuracy: ±0.2/100mm Temperature resistance:162℃ Tensile Strength: 44MPa Modulus of Elasticity:3500~7000MPa |

Auto parts, household appliances, electromechanical equipment | 350*350*420 |

|

High Performance Nylon | The surface is grainy and black. Toughness: good toughness and strength, high fracture ductility. |

Density: 1.3g/cm^3 Working Accuracy: 0.05~0.1mm Temperature resistance:175℃ Tensile Strength: 48MPa Modulus of Elasticity: 1700MPa |

Auto parts, household appliances, electromechanical equipment | 380*284*380 |

|

Photosensitive resin (domestic 9400) |

The surface is smooth and white, which can be used for oil injection coloring treatment. Toughness: the material is brittle and suitable for ordinary assembly. |

Density: 1.3g/cm^3 Working Accuracy: ±0.15/100mm Temperature resistance:46℃ Tensile Strength: 27~31MPa Modulus of Elasticity: 2178~2222MPa |

Automobile, consumer electronics, electromechanical, art | 800*800*450 |

|

Yellow High toughness resin | The surface is smooth and light yellow, which can be used for oil injection coloring treatment. Toughness: the strength and toughness are better than photosensitive resin-9400. |

Density: 1.15g/cm^3 Working Accuracy: ±0.15/100mm Temperature resistance:46℃ Tensile Strength: 45~58MPa Modulus of Elasticity: 2685~2775MPa |

Automobiles, medical,consumer electronics, etc | 800*800*550 |

|

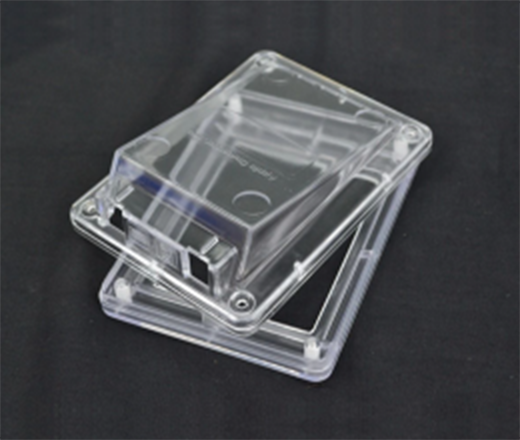

Transparent resin | The surface is smooth, transparent, slightly laminated, and the transparency of some inner cavity structures is slightly poor. Toughness: the material is brittle and suitable for ordinary assembly. |

Density: 1.12g/cm^3 Working Accuracy: ±0.3/100mm Temperature resistance:40-51℃ Tensile Strength: 450MPa |

Automobile, consumer electronics, electromechanical, art | 600*600*400 |

|

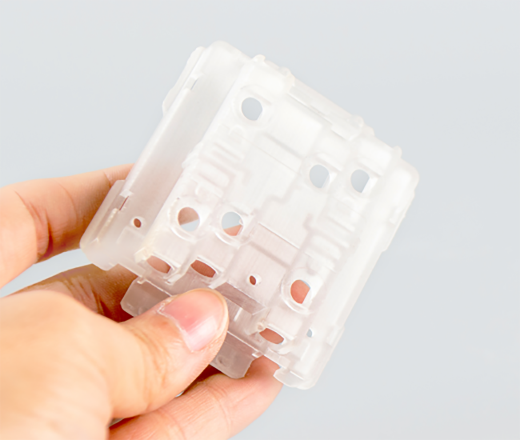

Translucent resin | The surface is smooth, translucent and slightly laminated. Toughness: the material is brittle and suitable for ordinary assembly. |

Density: 1.12g/cm^3 Working Accuracy: ±0.3/100mm Temperature resistance:40-51℃ Tensile Strength: 450MPa |

Automobile, consumer electronics, electromechanical, art | 600*600*400 |

|

high temperature resistant resin | The red translucent high-temperature resistant resin is suitable for rapid molding, temperature resistance demand products. (The thickness should be more than 2mm) |

Working Accuracy: ±0.15-0.5/100mm Temperature resistance:150℃ Tensile Strength: 42.7MPa Modulus of Elasticity: 3235MPa |

Arts and Crafts | 600*600*400 |

|

Black resin | The surface is smooth and gray black. Toughness: good toughness and strength. |

Density: 1.18g/cm^3 Working Accuracy: ±0.15/100mm Temperature resistance:58~69℃ Tensile Strength: 41~58MPa Modulus of Elasticity: 2722~2792MPa |

Master model in automotive, medical, consumer electronics and other industrial fields,Conceptual model, general components, production of functional components. | 600*600*400 |

|

Stainless Steel A316L | The surface is grainy and gray. Toughness: excellent corrosion resistance, high temperature resistance and creep resistance. |

Density: 7.98g/cm^3 Working Accuracy: ±0.3/100mm Temperature resistance:1100℃ |

Auto parts, household appliances, electromechanical equipment | 325*325*400 |

|

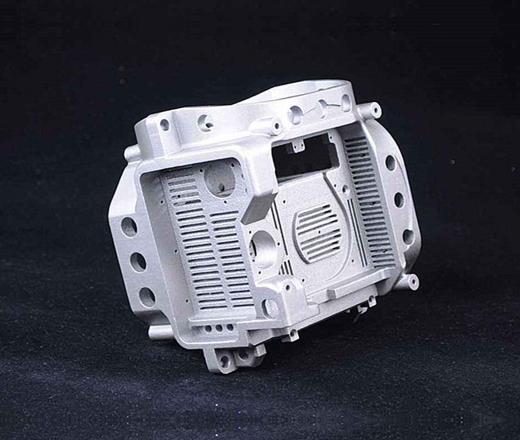

AlSI10mg Aluminum Alloy | The surface is grainy and gray. Toughness: good corrosion resistance, good casting performance and wear resistance. |

Density: 2.82g/cm^3 Working Accuracy: ±0.3/100mm Temperature resistance:1200℃ |

Auto parts, household appliances, electromechanical equipment | 325*325*400 |

|

Ti6A14V Titanium Alloy | The surface is grainy and gray. Toughness: low strength, high plasticity, high thermal strength, good corrosion resistance and good low temperature performance |

Density: 4.52g/cm^3 Working Accuracy: ±0.3/100mm Temperature resistance:850℃ |

Automobile, consumer electronics, electromechanical, art | 150*150*200 |

Notice:

- ● The PCBWAVE 3D printing online quotation is calculated according to the weight of printing materials, and other processes need to be charged additionally, such as surface treatment, etc

- ● 3D printing file format supported by PCBWAVE: STEP, STP, IGS, IGES, STL, OBJ, 3DS.

- ● Product details need to provide: product dimension, precision tolerance, quantity, materials, surface treatment, and other special requirements.

- ● The drawing is a composite model, so please clarify what you need, splitting printing or overall printing.

-

● Properly modify or design the drawing as per customers’ requirements.

Reference and specification

Reference and specification

- ● Quality: PCBWAVE makes the commitment that carefully and efficiently process every product complying fully with customers’ requirements. PCBWAVE regards quality as its priority. ISO9001 certificate is the basic requirement. PCBWAVE ensures the proper operation of its quality control system and guarantees the quality of all the products/parts ordered by us. Before producing any parts, engineers from PCBWAVE will check and confirm the customer’s 2D drawings and 3D files, making sure there is no mistake or unachievable technical requirements.

- ● Lead time: It usually takes 1-3 days for online 3D printing, but it’s finally determined by the products’ complexity.

- ● Rework & Refund Policy: PCBWAVE is also committed to becoming a trustworthy manufacturing service provider and it has an extremely customer-oriented rework and refund policy. Customers only need to provide photos or video to show the disparities, PCBWAVE will take relevant measures to ensure customer satisfaction.

- ● Company commitment: Create value for customers, provide the best quality and service, satisfied lead time, and after-sales for customers at the best price.

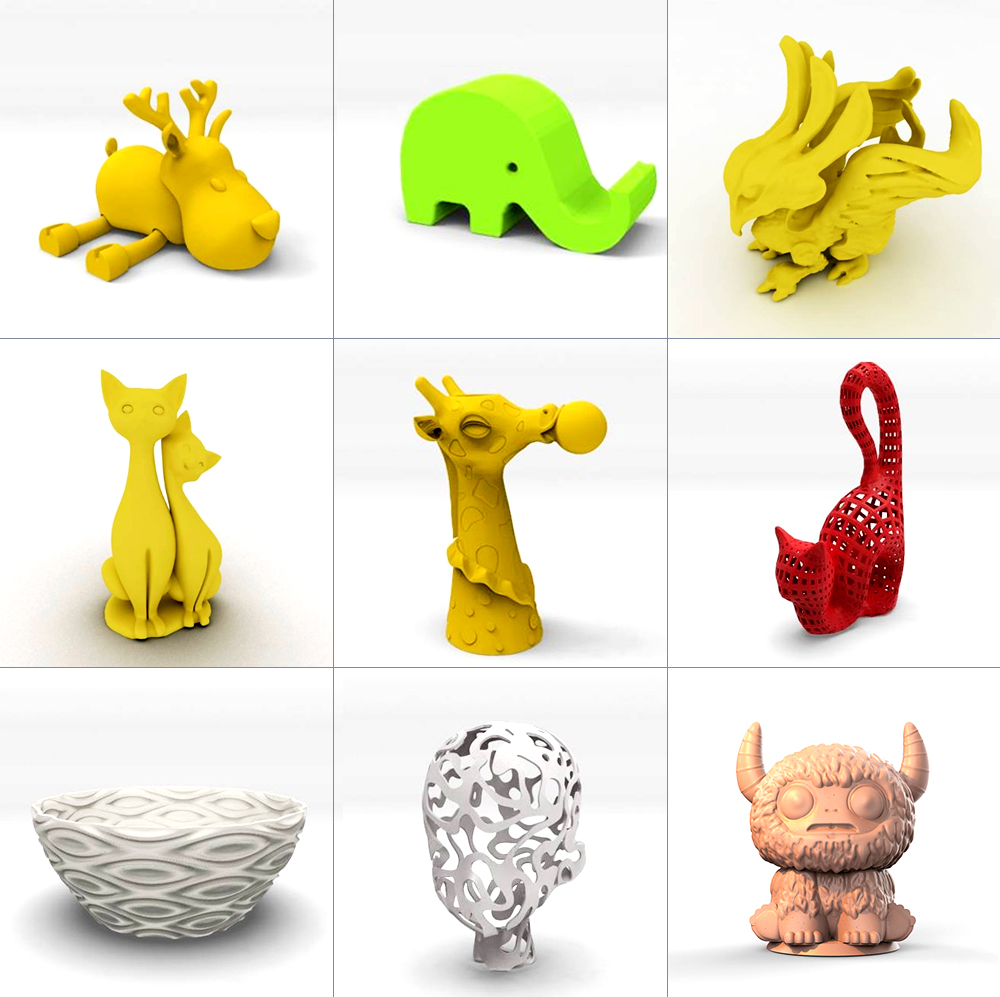

3D printing models display

Just for reference, you can find many free 3D printing files online, or you can design them yourself.

3D模型效果